My work as a student researcher with the

BYU Compliant Mechanisms and Robotics Group

What is a compliant mechanism?

A mechanism is a structure or system capable of transmitting force and motion. A compliant mechanism transfers force and motion through the deflection of flexible members. Common examples include a hunting bow, the hinge in a ketchup bottle cap, or the snap buckle on a backpack strap. As a part of the BYU CMR group, I solve problems using compliant mechanism theory and many other engineering principles.

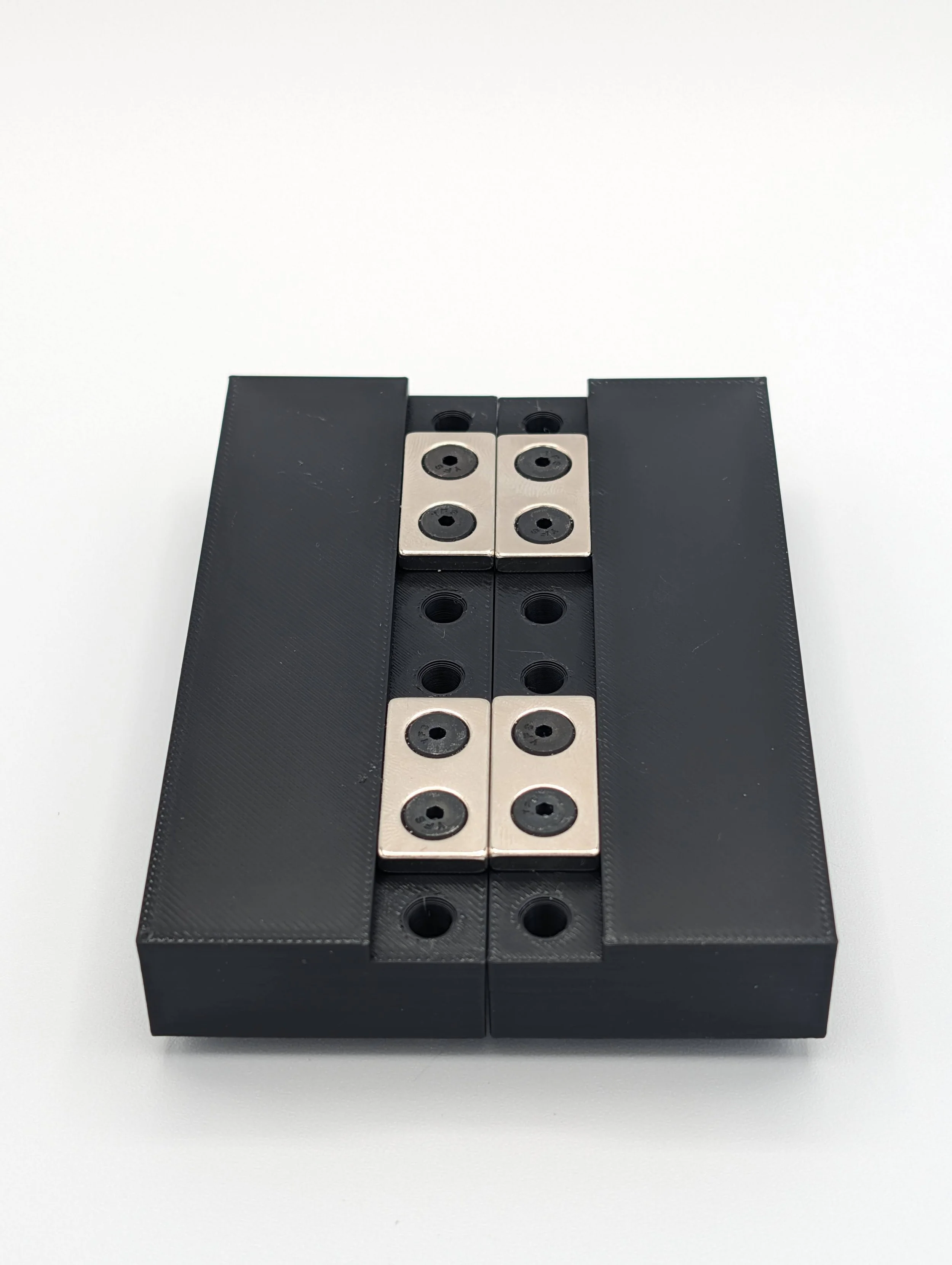

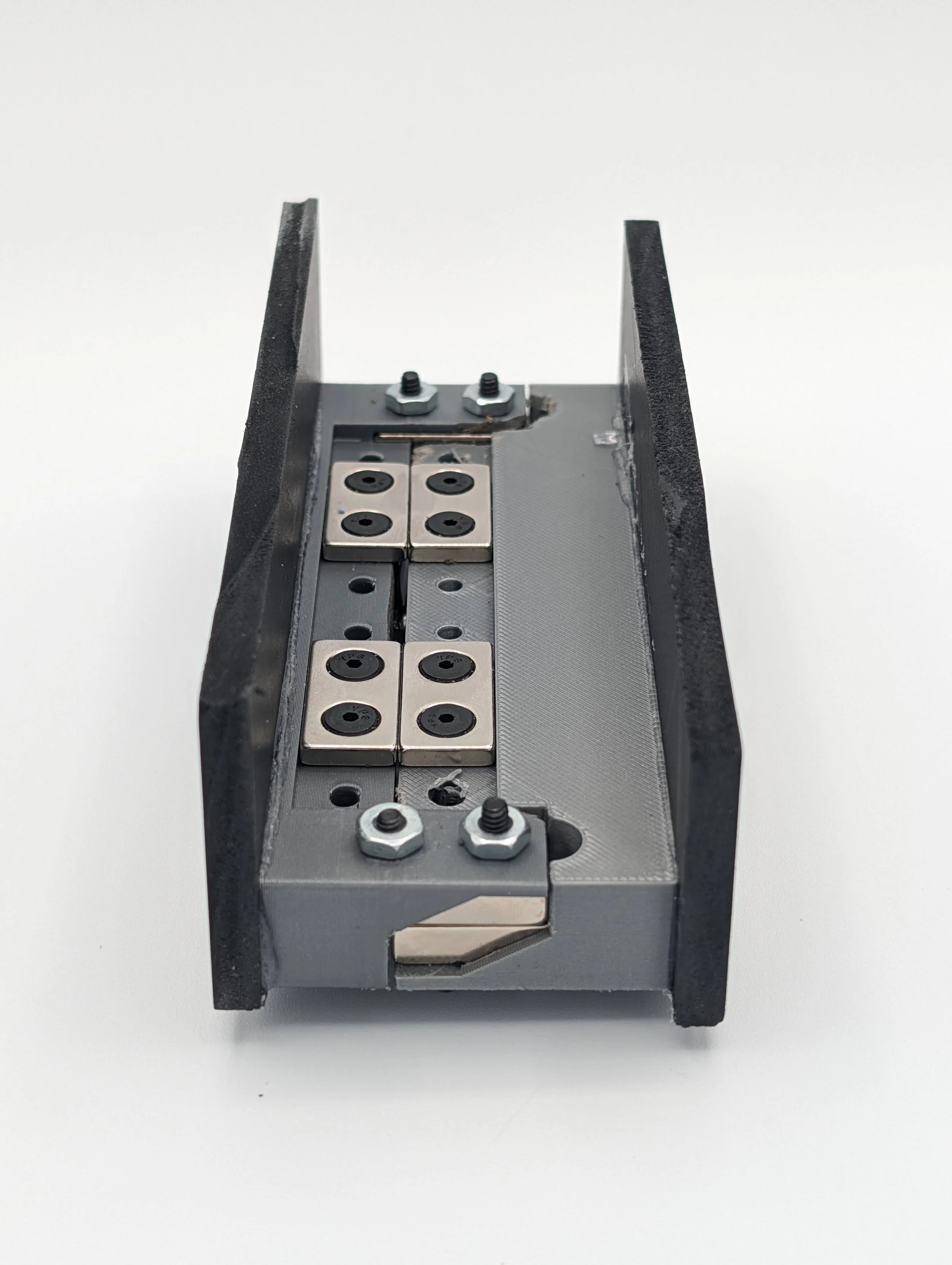

I had the privilege of working with Hunter Pruett and other excellent students during my time as an undergraduate in the CMR lab. We worked on a deployable satellite project for the Air Force Research Laboratory, and I was tasked with some of the prototyping. Specifically, I helped to explore post-deployment stabilization methods using magnets and compliant springs. I designed, 3D printed, and assembled the prototypes shown here. Our work was published here, and the pictures to the right show some of the prototypes I made. You can read more about this project in the article I wrote about magnets published here.

Undergraduate Work

Graduate Work

Researchers estimate that approximately 2.3 million Americans live with some form of amputation in the year 2025 and that more than 300,000 Americans undergo transtibial (between knee and ankle) or transfemoral (between hip and knee) amputation every year. The number of people living with amputation is expected to increase to 3.6 million by 2050 [1–3]. I am passionate about my research because improving prosthetic legs has the potential to positively impact millions of people. In collaboration with my fellow students at BYU as well as other excellent researchers at the University of Notre Dame, I am working to add compliance to standard and novel prosthetic leg components.

[1] M. Caruso and S. Harrington, “Prevalence of Limb Loss and Limb Difference in the United States: Implications for Public Policy,” Avalere Health, Feb. 2024.

[2] K. Ziegler-Graham, E. J. MacKenzie, P. L. Ephraim, T. G. Travison, and R. Brook- meyer, “Estimating the Prevalence of Limb Loss in the United States: 2005 to 2050,” Archives of Physical Medicine and Rehabilitation, vol. 89, no. 3, pp. 422–429, Mar. 2008.

[3] T. R. Dillingham, L. E. Pezzin, and E. J. Mackenzie, “Limb Amputation and Limb Deficiency:,” Southern Medical Journal, vol. 95, no. 8, pp. 875–883, Aug. 2002.

Optimizing Prosthetic Legs

Image credit: Adobe Stock Images

Our collaborators at the University of Notre Dame discovered that adding a torsional spring in parallel with the motor in a prosthetic leg can reduce the motor’s energy and torque needs for a variety of daily tasks [1]. I am working with my lab at BYU to find novel ways to add compliance and springiness to traditional prosthetic leg components to meet those torsional spring requirements. We’ve come up with a lot of ideas, and I have specifically been working on a novel torsional spring that could potentially replace the pylon (the vertical metal strut attaching a user to their prosthesis) in a traditional prosthetic leg. We refer to this spring as the Nested Split Tube (NST) joint.

[1] K. Yang, M. Dickens, J. Schmiedeler and E. Bolívar-Nieto, "Extending the Benefits of Parallel Elasticity Across Multiple Actuation Tasks: A Geometric and Optimization-Based Approach," in IEEE/ASME Transactions on Mechatronics, doi: 10.1109/TMECH.2025.3583658.

Adding Clever Springs

Nested Split Tube (NST) Joint

The Nested Split Tube (NST) joint takes advantage of the reduction in torsional rigidity introduced into a tube by an axial slit. These simple compliant mechanisms are called split tube flexures, and they were first described by [1]. By nesting multiple split tubes of varying radii within each other and attaching them to one another on alternating ends, we create a tube with a much larger effective length than its individual tube length. This allows for greater angular deflection and makes for an energy dense torsional spring.

[1] Goldfarb, M., and Speich, J. E. (September 1, 1999). "A Well-Behaved Revolute Flexure Joint for Compliant Mechanism Design." ASME. J. Mech. Des. September 1999; 121(3): 424–429. https://doi.org/10.1115/1.2829478